Graphitization

Introduction

Graphitization occurs when carbon or chromium-free low alloy steels operate above a critical level of temperature for a long period of time. The mechanism and root cause are well understood, although the ability to predict when a tube may fail by graphitization remains limited.

Description

Mechanism

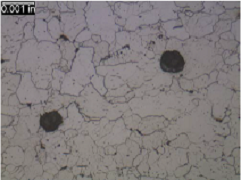

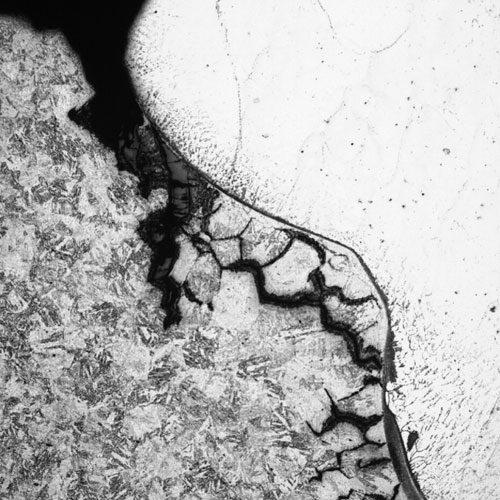

Graphitization is a form of damage that is unique to tubes fabricated from carbon or chromium-free low alloy steels that operate in the superheater or reheater sections of a boiler. The mechanism involves the decomposition of the original iron carbides into ferrite and graphite (the true equilibrium phases at temperatures below the transformation range) following prolonged exposure of the material to temperatures in the range of 425-700°C (800-1290°F). The graphite particles created during this decomposition can be present as individual spheroids (nodules) randomly distributed throughout the material structure, or they can be present as continuous or semi-continuous graphite “chains” (aligned nodules). Because graphite has very limited ductility, when the graphite particles become aligned into “chains,” the mechanical integrity of the tube is compromised and failure can occur. Chain type graphitization is mostly associated with the heat affected zones of welds; however, it can also occur far away from any welds. Note that spheroidization, which is a characteristic of thermal degradation, is a competing mechanism to graphitization at higher temperatures.

Typical Locations

Because graphitization only occurs following prolonged exposure to temperatures in the range of 450-700°C (840-1290°F), failures due to this mechanism normally occur in the superheater and reheater sections of a boiler.

Features

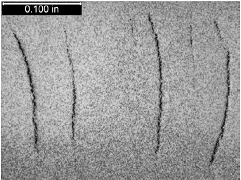

- Brittle fracture appearance

- Graphite nodules observed within microstructure

Root Causes

The single root cause of graphitization is the prolonged exposure of a susceptible material to temperatures within the graphitizing range for that alloy.

Corrective Actions

Once a boiler tube has failed due to graphitization, the primary challenge is to identify the extent of graphitization in other tubes in the section where the failure occurred. The ability to characterize the amount and distribution of sub-surface graphite using standard non-destructive examination techniques is limited at this time. Eddy-current testing and metallographic replication can provide information only about the size and distribution of graphite particles at or near the surface of a tube. Neither ultrasonic testing nor radiography has proven reliable for the detection and characterization of graphite particles. Once it is known that a problem with graphitization exists, temperature data from the terminal tubes for individual assemblies can be helpful in focusing sampling efforts.

Once all tubes with an objectionable level of graphitization have been identified, those tubes must either be repaired or replaced. Repair is only an option when the chain-type graphite is confined to the weld HAZ. Depending on the actual operating metal temperatures of the tubing to be replaced, as well as the desired span of serviceability, replacement can be in kind or can involve an upgrade to a chromium-bearing low alloy steel, with a minimum of 0.5% chromium considered to be adequate to avoid any possibility of graphitization at elevated temperatures.

SI Services

- Mechanism verification through destructive metallurgical analysis

- Assistance with determination of extent of damage through review of relevant operating/temperature data and failure history, as well as metallurgical analysis of supplementary samples to refine scope or repair and/or replacement

- Recommendation of replacement material based on operating conditions and future anticipated unit service

- Assistance with repair/replacement actions