Hydrogen Damage

Introduction

Hydrogen damage (HD) is the most frequently occurring of the underdeposit corrosion (UDC) mechanisms and remains prevalent in fossil plant boilers and combined cycle plants with heat recovery steam generators (HRSGs).

Description

Mechanism

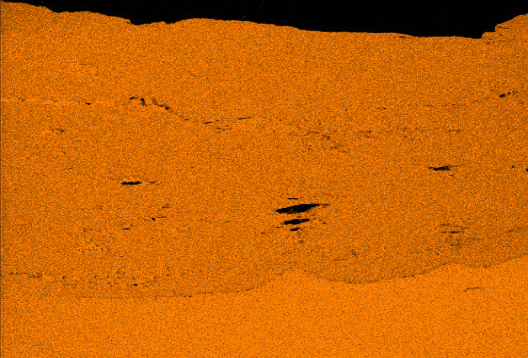

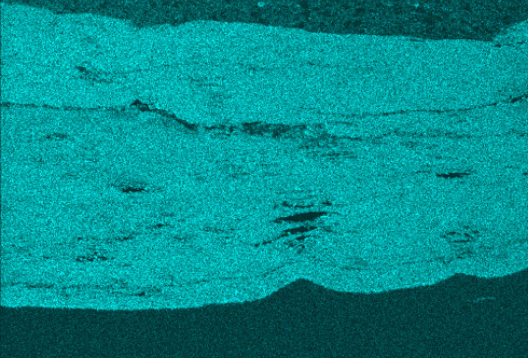

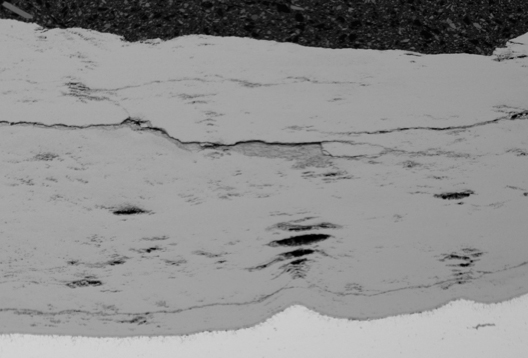

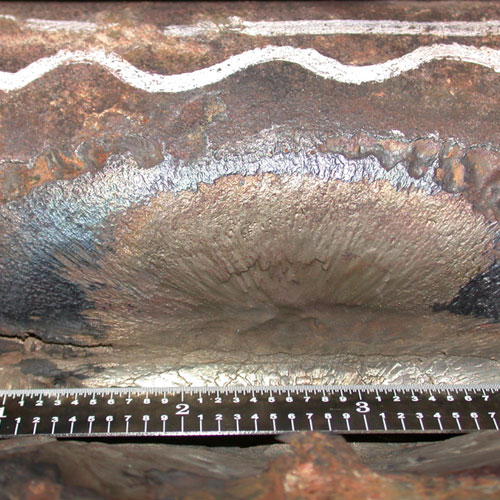

Hydrogen damage requires a combination of heavy internal deposits and acidic contamination. The first step leading to damage is when excessive deposits are transferred and deposited in the boiler. If an acidic contaminant is introduced it can concentrate beneath the heavy internal deposits. The resulting acidic environment can affect the magnetite growth process. Magnetite will grow at the surface, break off, and then another layer starts to grow. This repetitive process produces a thick multilaminated oxide layer that grows at a quick rate and promotes further corrosion. Hydrogen generated by corrosion at the tube surface will react with the iron carbide (Fe3C) in the tube material to form methane (CH4). Because neither molecular hydrogen nor methane easily diffuse through the steel, the gases accumulate, primarily at the grain boundaries. Eventually, gas pressures will cause separation of the metal at grain boundaries, producing discontinuous intergranular separations (fissures). As fissures accumulate, tube strength decreases until tube stresses exceed the tensile strength of remaining intact tube metal. Tubes fail in a brittle manner.

Typical Locations

- ID surface of hot side of tubes

- Highest heat flux areas

- Near flow disruptors: joints, bends, improper welds, etc.

Features

- Waterside mechanism

- Thick-edged failures, often window blowouts

- Gouging on ID surface

- Thick deposits within gouge (sometimes deposits are lost during failure)

- Chlorine concentrated at base of gouge

- Intergranular fissures in microstructure

Root Causes

Hydrogen damage occurs where high levels of deposits are present, creating a favorable site for underdeposit corrosion. The mechanism requires both high deposits and the ingress of acidic contaminants into the cycle (usually chloride or sulfate). Poor feedwater treatment often results in high corrosion product levels. Deposits are most often the result of corrosion or flow-accelerated corrosion in the condensate/feedwater system in conventional plans and the low pressure part of the HRSG, leading to transport of copper and/or iron into the waterwalls of conventional boilers or into the HP evaporator circuit in HRSGs. Deposition can also be influenced by disruptions to the internal flow in the boiler waterwall or HRSG evaporator tubing, or by flame impingement and burner misalignment. Ineffective chemical cleaning or incomplete flushing may allow deposits to remain or concentrate, and may also be a source of anionic contamination when inorganic acids are used as the solvent. Contaminant ingress can occur as a result of operating with small condenser leaks over a prolonged period or large condenser leaks for a short period of time. Chemical cleanings that are warranted based on deposit loading or in combination with a serious condenser leak are often delayed. Regenerant chemicals from the makeup or deep bed condensate demineralizer, as well as drips from auxiliary systems such as heater drips, may also be sources of acidic contamination. Process return streams from offsite steam systems may be another source of both corrosion products and acid contaminants. The online chemistry instrumentation must be capable of identifying condenser leaks or other sources of contaminant ingress and of alerting operations personnel to their presence.

Corrective Actions

Hydrogen damage can be detected using ultrasonic techniques to identify areas with heavy wall loss. Failed tubes should be metallographically analyzed to confirm the failure mechanism. After the mechanism is confirmed, the root cause of the damage should be identified. The plant cycle chemistry should be reviewed and optimized to prevent future damage.

Damaged tubes can be replaced after they have been located. Pad welding should not be used to repair damaged tubes, as excessive penetration of the weld can lead to flow disruptions and reinitiate the damage. Chemical cleaning is recommended to remove heavy deposits.

SI Services

- NDE/inspection services to define the geography of damage using ultrasonic testing (UT) for conventional boilers. Conduct fiber optic or other visual techniques for HRSGs.

- Provide recommendations for appropriate tube sampling locations for conventional and HRSGs.

- Mechanism identification through comprehensive metallurgical analysis of the failure situation and/or morphology of the internal indigenous oxide and deposits.

- Plant cycle chemistry program review and FAC assessment and benchmarking, typically completed during a one day site visit. Assess plant practices with respect to the number of repeat situations that can increase the likelihood of hydrogen damage. Provide a suggested action plan to address deficiencies in the chemistry program and repeat situations to include monitoring of feedwater corrosion products and instrumentation to adequately monitor chemistry around the cycle.

- Support the implementation, review and follow-up of the action plan and assess the results. Provide support and guidance to effectively clean the boiler or HP evaporator circuit to remove deposits.

- Provide advice and guidance on repair aspects.

Additional information

| Boiler Type | |

|---|---|

| Fuel | |

| Boiler Region | |

| Metallurgy | |

| Failure |