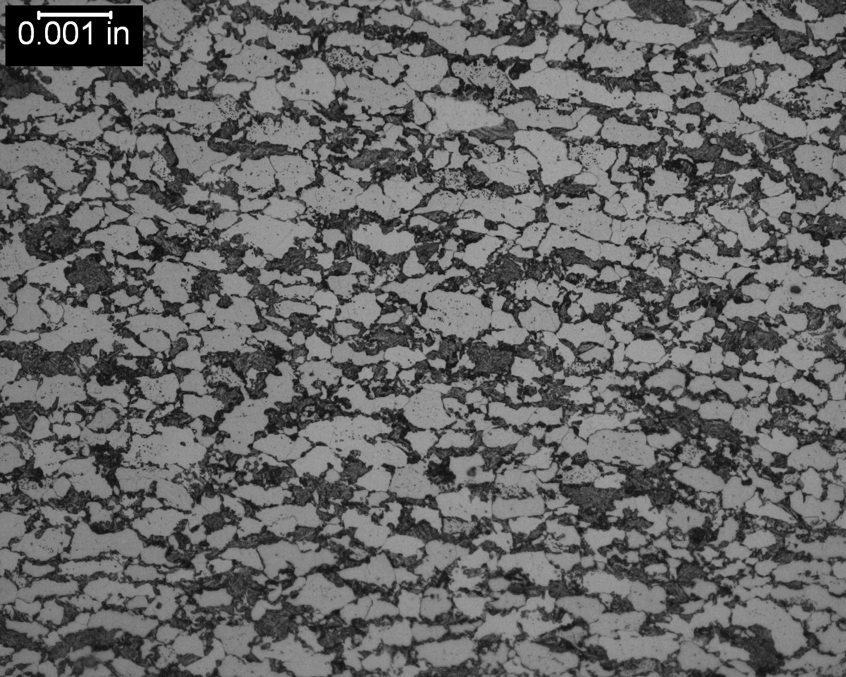

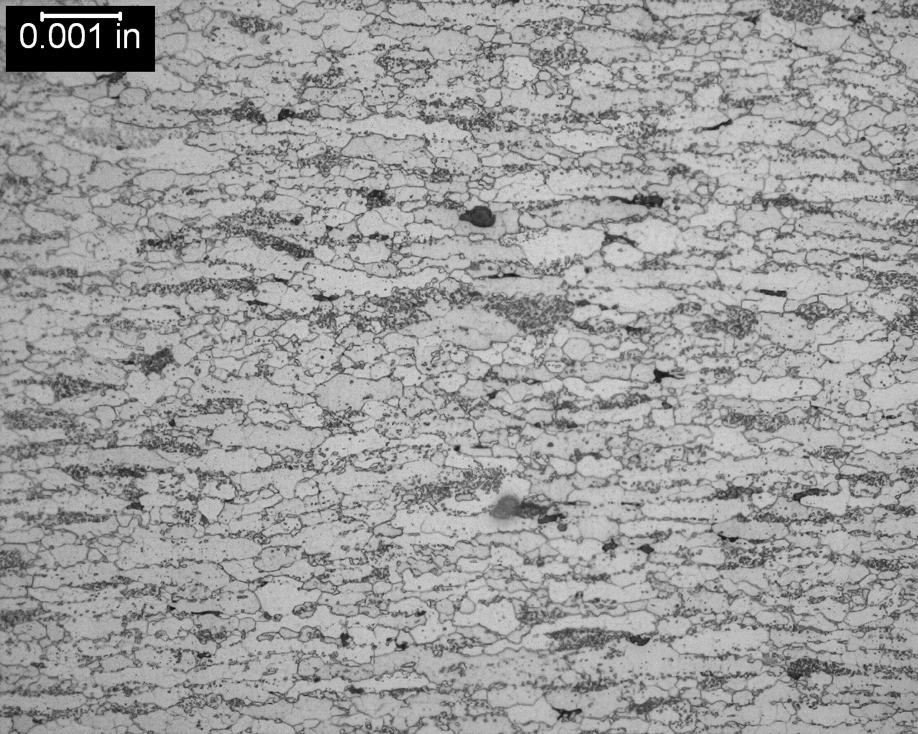

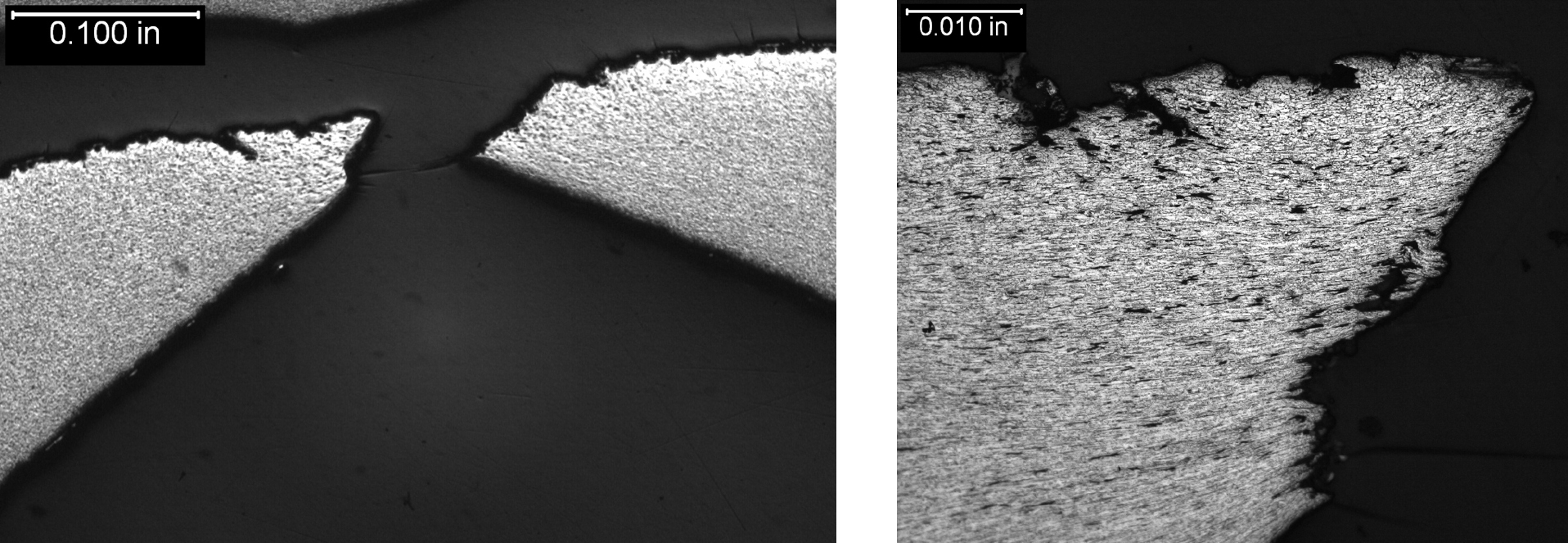

Metallographic images from the rupture, showing thinned rupture tips, grain elongation from the hot tensile overload, and grain boundary voids

Short Term Overheating Water Walls

Introduction

Short term overheating occurs in water wall tubes because of lowered coolant flow, excessive combustion gas temperature or a combination of both. The tube is subjected to excessively high temperature, which results in rapid failure.

Description

Mechanism

Short term overheating occurs in water wall tubes because of lowered coolant flow, excessive combustion gas temperature, or a combination of both. The damage occurs when the tube temperature rises above design limits for a brief period. Metal temperatures generally always exceed 850°F and often exceed 1350°F. At elevated temperatures, the tensile strength of the metal is markedly reduced. If temperatures rise to very high levels, failure will occur quickly.

Typical Locations

- Failures can occur anywhere in the water walls.

- Usually located in the high heat flux areas even if there is a flow disruption is lower in the furnace.

- Near or above the burners.

- Bottom of the nose arch.

Features

- Subcritical Temperatures (above design but below the lower critical temperature):

- Swelling and a thin edged “fish mouth” rupture.

- Microstructure and hardness values consistent with original material.

- Intercritical Temperatures (between the lower and upper critical temperatures)

- Swelling and a thin edged “fish mouth” rupture.

- Transformational microstructural products consistent with temperature at the time of failure.

- Higher hardness values at the failure site.

- Upper critical Temperatures (above upper critical temperature)

- Swelling and a thin edged “fish mouth” rupture.

- The material will be transformed to austenite, which subsequently transforms to martensite and bainite due to the quenching effects of the rupture.

- Higher hardness values consistent with the resultant microstructure.

If failure happens rapidly, bulging may be absent and the rupture can be violent, sometimes severely bending the tube and causing secondary metal tearing. Thick edged failures may also occur with this failure mechanism under specific circumstances.

Root Causes

To avoid repeat failures, the specific root cause as well as the extent of damage must be identified. There are three primary causes of short term overheating:

- Partial blockage due to maintenance activities.

- Partial blockage due to maintenance activities stem from tools left in the tubes, poor welding practices including machining or welding debris, or excessive weld penetration. These failures generally occur shortly after an outage. To verify the nature of the blockage, check the tube ID from header to header to locate the tool or debris and review records of recent maintenance activities for other suspected areas.

- Feed water corrosion product deposition on orifices.

- Feed water corrosion products can deposit on orifices over time and slowly reduce the flow to the tube circuit. Orifices should be visually inspected periodically to determine if the orifices are becoming fouled. In addition, monitor the pressure drop across the boiler circulating water pumps as changes may be indicating that the orifices are becoming fouled. The deposits which are typically very soft, and can be removed with compressed air or a suitable wire brush.

- Improper drum level control.

- Poor drum level control can lead to a steam bubble descending the downcomer and entering the water wall tubes. This usually happens on start up with a resulting failure soon afterwards, if the drum level is too low. This mechanism can also result from a low drum level but most often it is due to drum level surge on startup. A review of operating records including drum level and control will provide the necessary information.

Corrective Actions

Following a short term overheating failure, inspections must be conducted to assure that no additional tubes are affected. The scope of inspections can be extensive if a blockage is suspected to be widespread, as in the case of plugged orifices, or minor where only the failed tube is affected, as in the case of problems due to a recent maintenance activity. If the issue is thought to be widespread, a large scale inspection program may be necessary to locate the blockage, blocked orifices, or debris area in the header/tubes to correct the problem. If the issue is thought to be localized, only the failed tube requires an internal inspection from header to header and a visual examination of the outside for signs of swelling, especially upstream of the failure and slightly downstream of the failure. A go/no go gage that is approximately the size of the specified OD can be used to assess tube swelling.

In all cases, the extent of damage must be identified and appropriate replacements installed. Very rarely can a materials solution be applied because of the rapid escalation of tube temperature. For specific root causes, the following actions should be taken.

- Tube blockage: the blockage must be removed prior to return to service.

- Orifice deposit buildup: the orifices should be inspected and excess deposits removed.

- Poor drum level control: procedures must be developed/followed to prevent entry of steam into the downcomers.

SI Services

- Plant operational and maintenance reviews and benchmarking of damage severity. Reviews not directed toward specific concerns such as short term overheating can identify attributes which need improvement to avoid susceptibility to other forms of tube damage.

- Laboratory analysis of damaged tubing to assess condition, identify the level of short term overheating and determine responsible mechanism.

- Assistance in root cause identification and verification.

- Assess plant practices with respect to a series of Repeat situations which if not corrected are known to substantially increase the risk of short term overheating.

- In situ NDE assessments to identify additional damaged tubing

- Provide guidance on repair procedures