Shock Wave Damage

Introduction

Various forms of explosives can be used to clean the gas path of superheater and reheater when extensive ash deposition is present.

Description

Mechanism

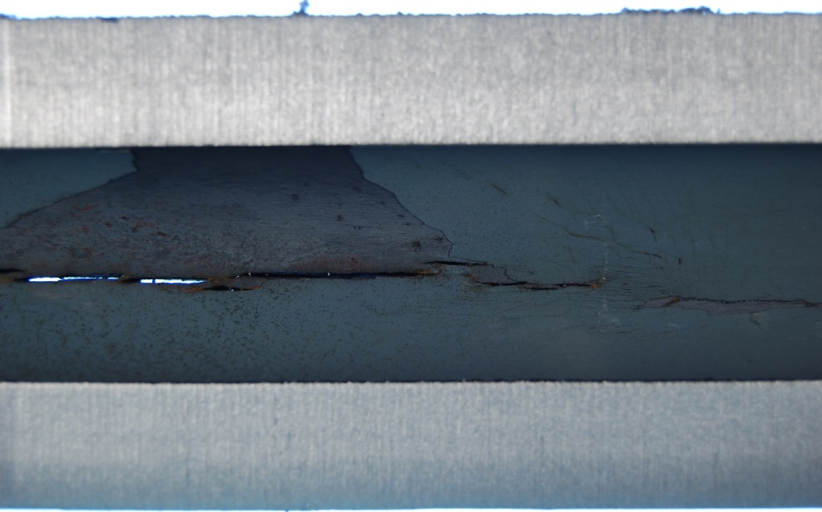

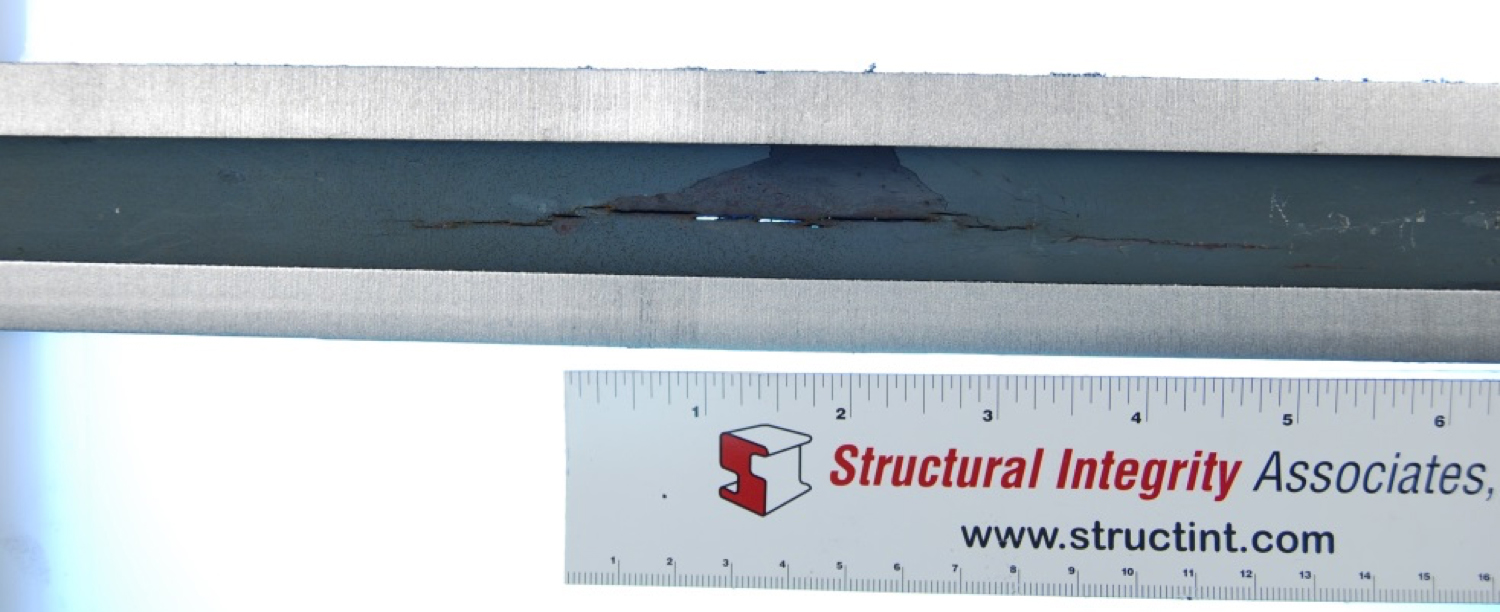

Shock wave damage results from the improper use of explosives. Failures occur when the shock wave is reflected from the back surface (the ID surface of the tube), and interacts with the incident shock wave as a stress wave. Damage forms when the magnitude of this tensile stress exceeds the inherent strength of the material.

Typical Locations

Features

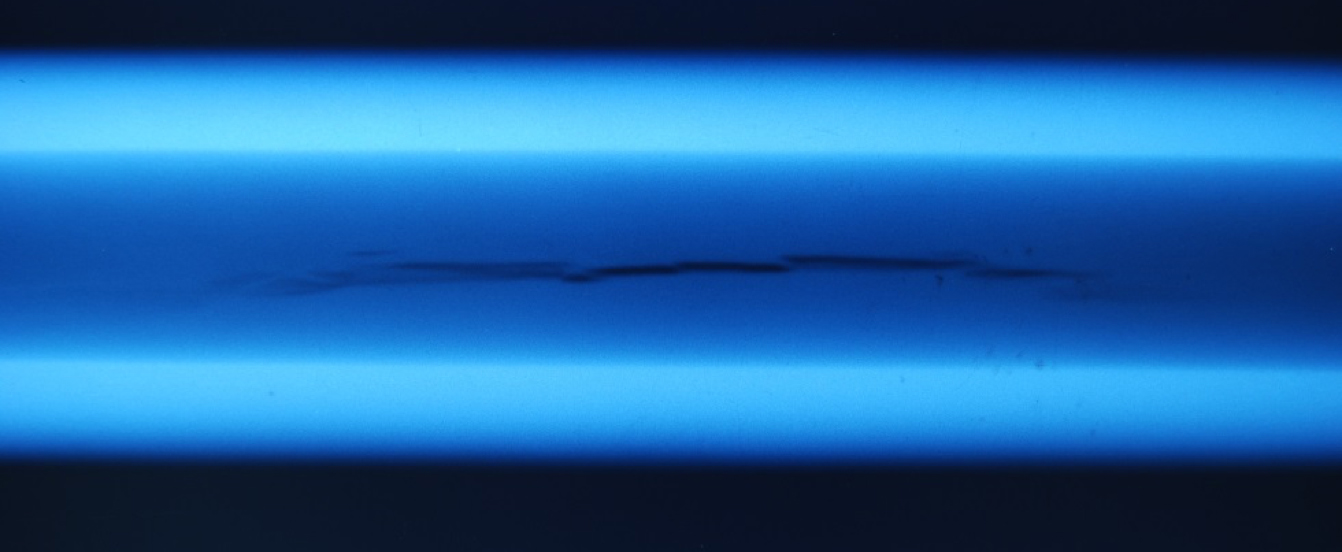

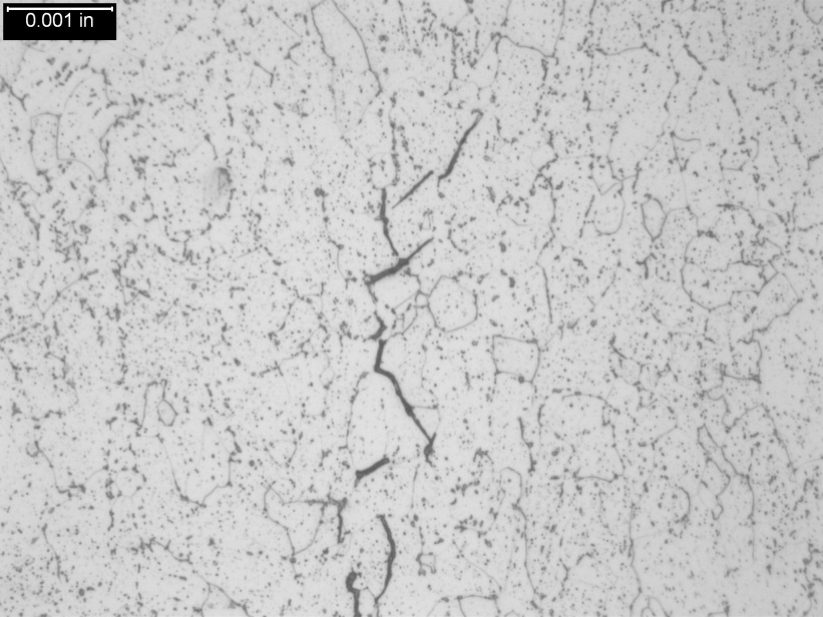

Cracks are brittle, intergranular, and initiate either subsurface, or at the OD or ID surface depending on the location of the shock wave. They may also exhibit secondary cracking that is not connected to the primary crack, which is characteristic of shock wave damage

Root Causes

Shock loading of boiler tubes during the detonation of explosives typically occurs because 1) the charge size is excessive; and/or 2) the charge is not positioned properly relative to a tube in a given area of the furnace. Therefore, the shock wave produced by the detonation is of a sufficient intensity to instigate brittle fracture in the tube wall.

Corrective Actions

A nondestructive examination, such as an RT inspection, can be performed to identify other potentially affected tubes. The locations of inspection should include all areas near detonation, especially the areas in the vicinity of the failure. Once the full extent of the damage is determined, then a plan of tube replacement can be developed. It is possible that tubes with incipient cracks will continue to fail in the future. For future operation, extreme care should be taken in the sizing charge and positioning explosives to minimize the risk of the shock wave damaging of tubes during slag removal in all assemblies when the explosive is used.