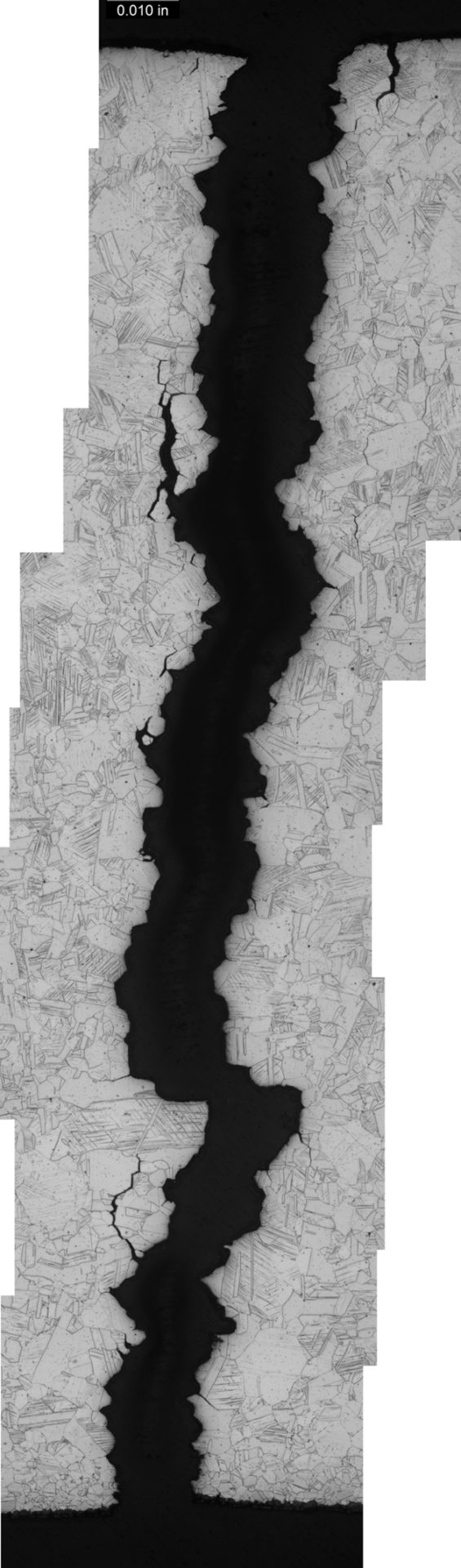

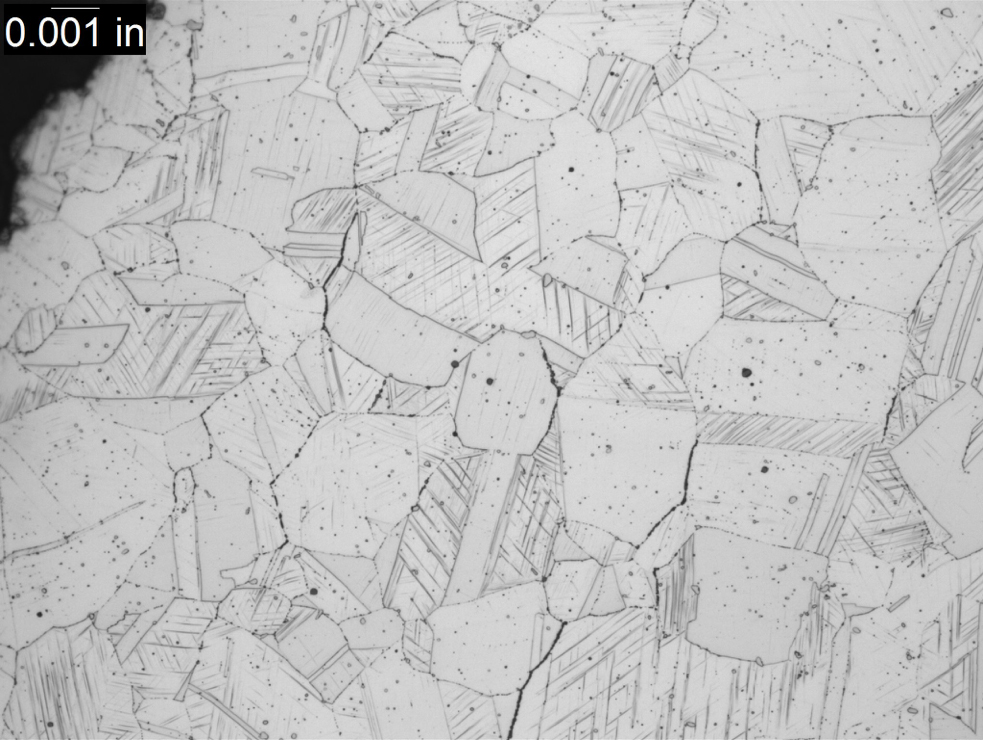

An overall, cross-sectional view of the intergranular crack with higher magnification views of some of the secondary grain boundary microfissures and voids B

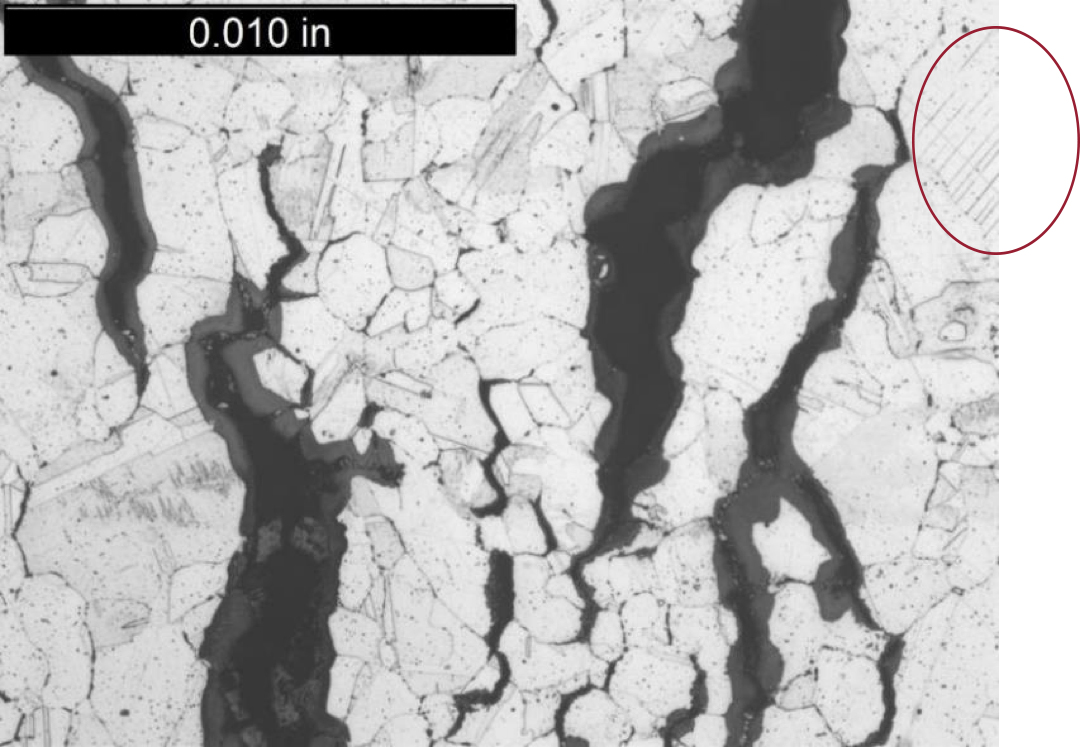

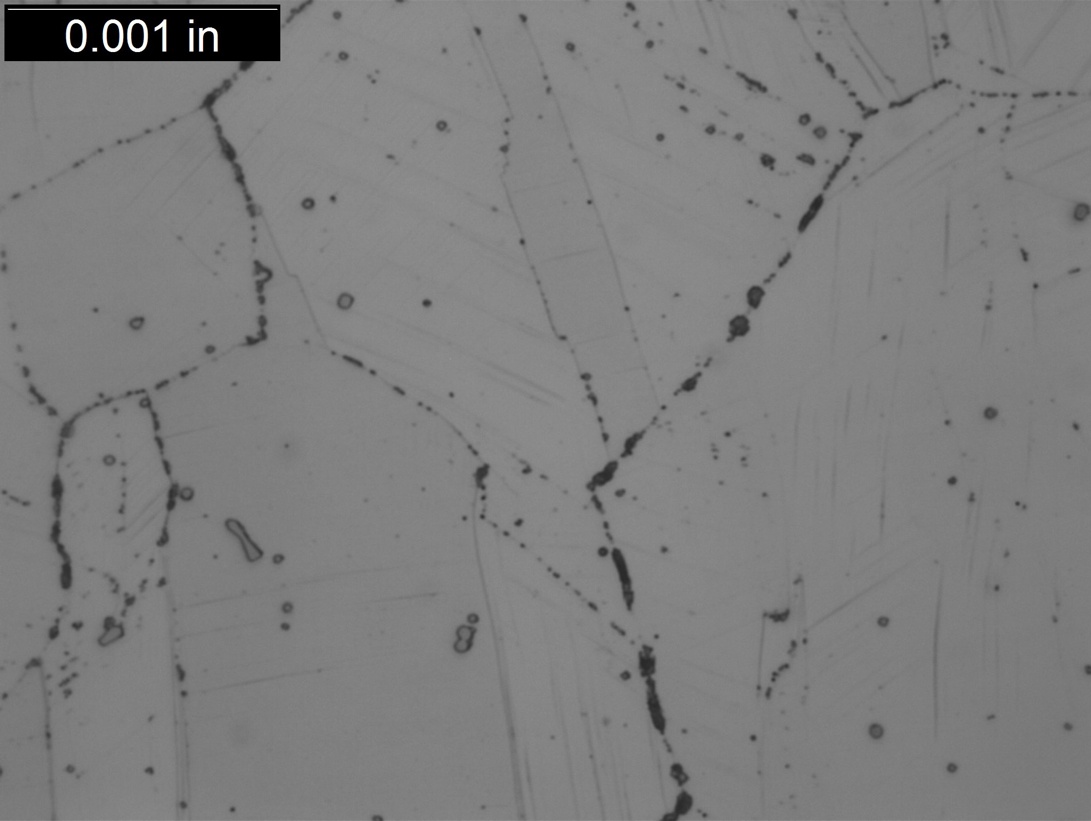

An overall, cross-sectional view of the intergranular crack with higher magnification views of some of the secondary grain boundary microfissures and voids C

Strain Induced Precipitation Hardening

Introduction

Strain-Induced Precipitation Hardening (SIPH) in Austenitic Stainless Boiler Tubes

Strain-Induced Precipitation Hardening, also known as SIPH, is a commonly misinterpreted boiler tube failure mechanism that occurs when austenitic stainless steel tubing is cold or warm worked during fabrication and then is installed either without an appropriate solution annealing heat treatment or with an improper solution annealing heat treatment. The basic mechanism and the root cause are understood, but the complex interaction between heat chemistry, quantity of cold or warm work, and subsequent thermal history makes it very difficult to predict under precisely what circumstances damage due to SIPH will result in failure of a boiler tube.

Description

Mechanism

SIPH occurs when a heat of austenitic stainless steel that contains certain precipitate-forming elements, such as niobium, titanium, vanadium, etc., either intentionally or as residuals, is cold or warm worked during processing of the material. The cold or warm working creates a large number of excess defects in the sub-structure of the material, which serve as preferred sites for precipitation of temper resistant carbides or carbo-nitrides when the material is heated to a temperature that is sufficiently high to allow the precipitation to occur but well below the solution annealing temperature. This can occur fairly rapidly during a poorly executed solution annealing heat treatment if the material does not reach the proper solution annealing temperature, or it can occur more slowly at typical operating temperatures for superheater or reheater tubing in utility-type boilers.

Once formed, the precipitates anchor the defects, which results in a substantial increase in the elevated temperature, or creep strength of the interior of the grains. At the same time, there is a narrow zone of material immediately adjoining the grain boundaries that remains largely precipitate-free, due to the diffusional characteristics of the grain boundary itself. Ultimately, the interior portion of the individual grains becomes very strong at elevated temperatures while the material immediately adjoining the grain boundaries become comparatively creep weak. In addition, any surface active elements that may be present in the material, such as arsenic, tin, antimony, etc., will tend to concentrate at the grain boundaries, further reducing the strength of the grain boundaries.

Regardless of when the precipitation occurs, once it has occurred and the interior of the grains have been strengthened and the grain boundary regions have been weakened, then any strain that is imposed on the material in response to an applied or residual stress is forced to concentrate in the grain boundary region, which serves to substantially magnify the strain’s effect. For example, in a situation where the bulk strain experienced by a segment of a cold-worked stainless superheater tube might be very small – a fraction of a percent – if the material has undergone the SIPH reaction, then the strengthened grain interiors will undergo no strain, while within the much smaller volume of the comparatively weak grain boundaries the accumulated strain will be orders of magnitude higher than the bulk level.

Typical Locations

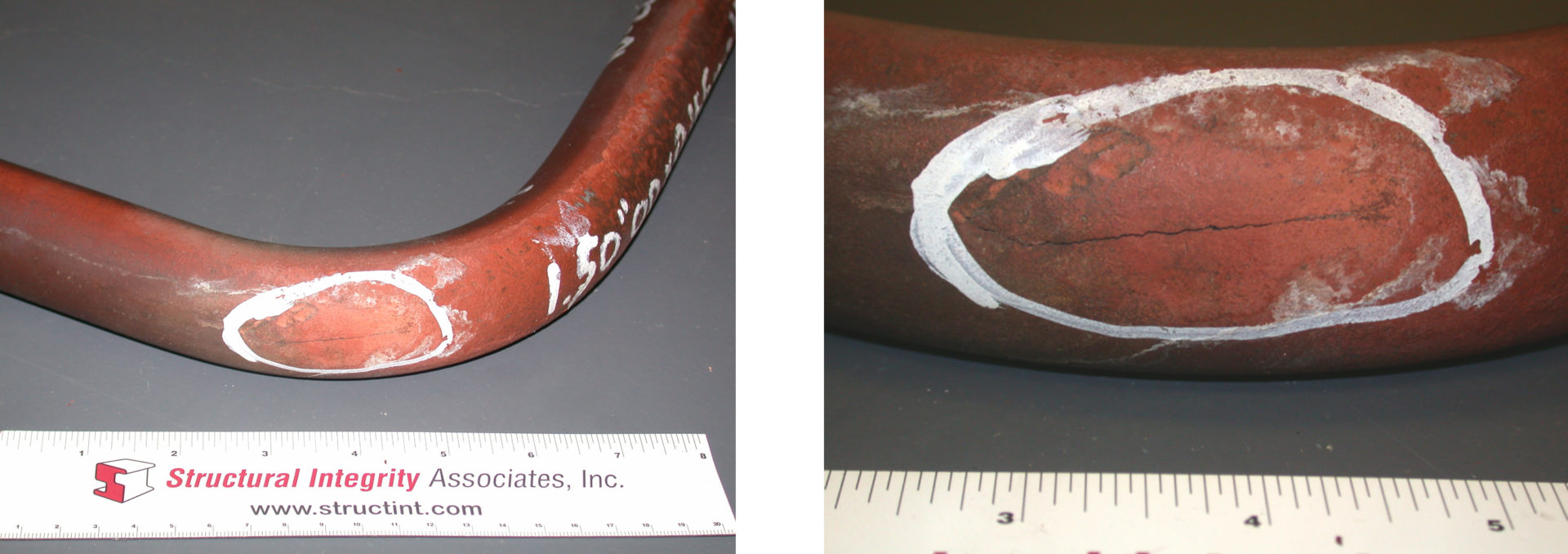

- Bends

- Offsets

- Swages

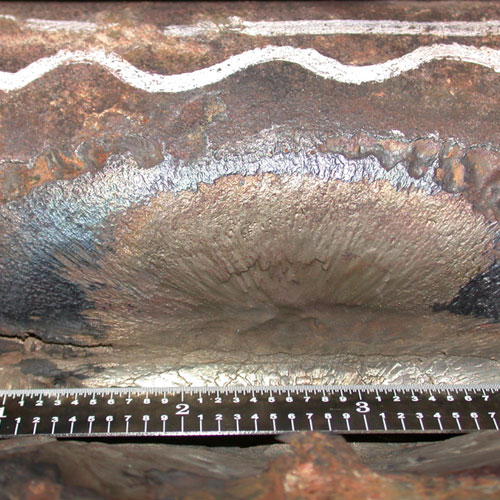

- Welded attachments

Features

- Can initiate at midwall

- Early stage damage consists largely of grain boundary cavities and microfissures

- Intergranular crack

Root Causes

The single root cause of SIPH is the failure to properly solution anneal a susceptible heat of austenitic stainless steel tubing that has been either cold or warm worked during fabrication.

Corrective Actions

Because the damage can initiate at the midwall, identifying damage tubes can be difficult. Digital radiography has been used for detection with partial success, being most effective when the cracking is at least moderately advanced. Linear phased array (LPA) can be used to detect damage that has not progressed to an advanced stage, supplemented by focused array to characterize the precise location and extent of the damage.

Once damaged tubes are identified, it may be possible to give the affected components an in-situ solution annealing heat treatment. Performing such a heat treatment requires that great care be taken in the planning and execution of the operation, but if the heat treatment is performed properly, the risk of any further damage due to SIPH can be eliminated. The cold or warm-worked areas can also be replaced with tubing that has been properly heat treated.

SI Services

- Mechanism verification through destructive metallurgical analysis. This step is particularly important, since there have been many more instances of incorrect diagnoses of SIPH than of accurate identification of SIPH as the primary damage mechanism.

- Assistance in the determination of the extent of damage through review of the material fabrication history carried out in conjunction with use of the appropriate non-destructive inspection techniques. Destructive examination of supplementary samples may be required to validate the non-destructive inspection results.

- Development of a specification for the purchase and fabrication of replacement material

- Assistance with repair/replacement actions, including management of in-situ heat treatment efforts.